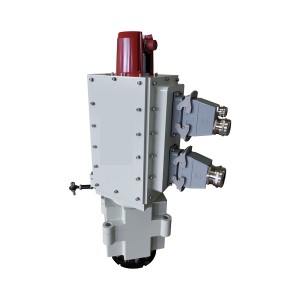

Engineering vehicle Slip Ring—360°Rotating -high reliability

SciTrue–An Expert of Slip Ring

Description

▲ Engineering machinery slip ring can transmit power, bus,CanBus signal, network signal and video signal, etc., It can measure angle by integrate encoder inside, also can integrate outside of hydraulic rotary center

▲ Compact structure, easy installation.

Engineering vehicle Slip Rings typically contain a number of power rings and signal rings transferring high currents and data to and from rotating components on the vehicle. These Slip Rings typically integrate positioning sensors (encoders, potentiometers), Fiber Optic Rotating Joint (FORJ), and Fluid Rotating Unions

The increasing complexity of modern military vehicles demands slip rings that provide reliable electrical interfaces between the stationary and rotating parts of these vehicles. slip rings have been chosen to operate on numerous vehicular programs to meet these challenges. M1 / A2 and M60 tanks, A2 / A3 Bradley Fighting Vehicles, Stryker, Light Armored Vehicles (LAVs), and V150 Commando Vehicles are just a small sample of these vehicular programs.

Technological developments have yielded stabilized gun systems, laser target acquisition and fire control systems, and high bandwidth data communications that create unique demands for vehicular slip rings. We meet all of these challenges effectively and economically.

Features

Typic Application

◆ Low current transmission loss, low temperature rise, stable performance, high reliability

◆ Strong environmental adaptability to shock, vibration, rain, flooding.

◆ The cable lead fly can be single or multiple lines according to the system space, and can be.

◆ Electrical Excavator

◆ Hydraulic aerial cage

◆ Fire fighting truck

◆ Crane truck

◆ Pumping Truck

Military Quality Fine Works

Operating Parameters

|

Enclosure |

IP67 |

|

Rotary Speed |

100rpm |

|

Rated Current |

2000A |

|

Rated Voltage |

10KV |

|

Number of Circuits |

100CH |

Let Rotation be Free